Information Source: http://www.npd-solutions.com/glossary.html

| ABC | see Activity Based Costing |

| ABM | see Activity Based Management |

| Acceptance Criteria | The criteria a product must meet to successfully complete a test phase or meet delivery requirements. |

| Acceptance Testing | Formal testing conducted to enable a user, customer, or other authorized entity to determine whether to accept a product or product component. |

| ACIS | A solid modeling engine or kernel used in a number of CAD systems. Having a common solids modeling engine allows more ready interchange of data between different CAD systems. |

| ACIS SAT | A file format for 3D solid geometry created by systems using the ACIS solids modeling engine. |

| Active Listening | A technique used to help communication among team members and project personnel. Active listening involves paying careful attention to what is being said, then rephrasing that information and feeding it back to the originator to ensure that what you think you heard is what they meant. |

| Activity Based Costing | Activity Based Costing is a costing and analysis method that associates resources and their costs to activities and then associates the costs of activities to cost objects (e.g., a product) based on a cost drivers which measure use of an activity by the cost object. These cost drivers, such as the number of persons performing work or the number of setups required per product reflect the consumption of activities by the products. |

| Activity Based Management | A discipline that focuses on the management of activities as a route to improving the value received by the customer and the profit received by providing this value. This discipline includes cost driver analysis, activity analysis, and performance measurement. |

| Additive Fabrication | Fabrication processes which add material using a variety of processes to create a final part or item geometry with a minimum of secondary processes required. The technologies involved have previously been associated with rapid prototyping, but when these technologies are able to directly produce parts for products, additive fabrication is a better description. Other related terms include layered manufacturing, digital fabrication, and direct digital manufacturing. See Direct Digital Manufacturing. |

| Adjacent Sector Innovation | A focused surveillance and innovation effort to explore how the organization’s technologies and products can be adapted and/or applied to adjacent market sectors or how concepts for products in adjacent sectors can be applied to a company’s products in its main sector. |

| Advanced Product Quality Planning | Advanced Product Quality Planning (APQP) is a segment of the QS-9000 process developed by the AIAG and used by the auto industry. It provides a quality framework to understand customer needs and determine all the actions with product and process design to assure that the production process can deliver products that satisfy those needs. This framework includes tools such as quality function deployment to understand customer needs and translate them into product and process characteristics, product and process design validation and verification, failure modes and effects analysis to counter or control potential failure, and control plans to insure critical product characteristics are achieved. |

| Advance Quality Planning | An assessment at the start of product development to identify problems with other similar products so that preventative steps or countermeasures can be taken with the new product. Also referred to as a like product and process review. |

| Affinity Diagram | Affinity diagrams or charts are a simple way for a group to cluster qualitative data and come up with a consensus view on a subject. It is often used with QFD to sort and organize the large amount of customer needs data. In this instance, statements of customer needs are written on cards or post-its. The cards or post-its are logically organized by the group and the group develops headings under which to cluster these needs. The cards or post-its are moved to the appropriate group headings. |

| AFD | See Anticipatory Failure Determination |

| Affordability | The characteristic of a product with a selling price that that is no more than its functional worth to a customer and is within the customer’s ability to pay. |

| AHDL | Analog Hardware Description Language (IEEE standard 1076.1) – describes the physical design, electronic behavior, logical structure and system annotation information for analog circuits. |

| AHP | See Analytical Hierarchy Process |

| AI | Artificial Intelligence |

| AIAG | Automotive Industry Action Group consist of the Big 3 auto manufacturers who have collaborated to develop standard such as QS-9000 and APQP (see Advanced Product Quality Planning). |

| AIM | Application Interpreted Model (STEP) – The model that describes the interpretation of the STEP integrated resources constructs that provide functional equivalence to the AP’s information requirements as specified in the application reference model. Required information documentation for the AIM includes the description of the entities of that information model and a summary of the rationale with which the resulting schema was derived from the application reference model. |

| Allocated Requirements | Allocated requirements are requirements that apportion all or part of the performance and functionality of a higher-level requirement on a lower-level element of a system. |

| Analysis of Variance | Analysis of Variance is a basic statistical technique for analyzing experimental data. It subdivides the total variation of a data set into meaningful component parts associated with specific sources of variation in order to test a hypothesis on the parameters of a model or to estimate variance components. |

| ALT | Accelerated Life Testing |

| Analytical Hierarchy Process | A decision making tool for complex, multi-criteria problems where both qualitative and quantitative aspects of a problem need to be incorporated. AHP clusters the decision elements according to their common characteristics into a hierarchical structure similar to a family tree. It involves building a hierarchy (Ranking) of decision elements and then making comparisons between each possible pair in each cluster (as a matrix). This gives a weighting for each element within a cluster (or level of the hierarchy) and also a consistency ratio (useful for checking the consistency of the data). By reducing complex decisions to a series of simple comparisons and rankings, then synthesizing the results, AHP helps arrive at the best decision and also provides a clear rationale for the choice made. The Analytical Hierarchy Process Model was designed by TL Saaty as a decision making aid. |

| ANOVA | see Analysis of Variance |

| ANSI | American National Standards Institute |

| Anticipatory Failure Determination | Anticipatory Failure Determination (AFD) is a failure analysis method. Like FMEA, it has the objective of identifying and mitigating failures. Rather than asking developers to look for a cause of a failure mode, it reverses the problem by asking developers to view the failure of interest as the intended consequence and try to devise ways to assure that the failure always happens reliably. This viewpoint then facilitates better identifying steps to avoid the failure. |

| AOI | Automated Optical Inspection |

| AP | Application Protocols (STEP) – These specify implementable STEP data constructs for communicating information in a defined application context. It defines the context for the use of product data and specifies the use of the base standard in that context to satisfy an industrial need. AP’s are Parts in the 200 series of the STEP standard. |

| API | 1. Application Protocol Interface 2. Application Programming Interface – the standard set of functions provided by a program or operating system to allow for integration of other software. Two programs linked via an API can both be altered and still work together so long as both conform to the API. |

| Apportionment | The assignment of goals such as reliability from system to subsystem in such a way that the whole system will meet the required goal. |

| APQP | See Advance Product Quality Planning |

| AQP | See Advance Quality Plan |

| Architecture | The design and interconnection of the main components of a hardware/software system. The framework and interrelationships of elements of a system. |

| Architectural Principles | Architectural Principles are statements of preferred architectural direction or practice. Each principle should be stated in such a way that one will know if the architecture has the characteristics expressed by the principle. Principles need to be rationalized, stating why the principle is preferred. |

| ARIZ | Russian acronym for Algorithm of Inventive Problem Solving (see Theory of Inventive Problem Solving) |

| ARM | Application Reference Model (STEP) – An information model that formally describes the information requirements and constraints for an application area. The information model uses application-specific terminology and rules familiar to an expert from the application area. The model is independent of any physical implementation and must be validated by experts from the application area. |

| ARO | After Receipt of Order – usually a measure of the days, weeks or months until a product can be designed and delivered. |

| AS9100 | AS9100 is an international quality management standard for the aerospace industry published by the Society of Automotive Engineers; also published by other organizations worldwide, as EN9100 in Europe and JIS Q 9100 in Japan. The standard is controlled by the International Aerospace Quality Group. |

| ASIC | Application Specific Integrated Circuit – a semi-custom chip used in a specific application that is design by integrating standard cells from a library. |

| ASME | American Society of Mechanical Engineering |

| ASQC | American Society of Quality Control |

| Assignable Cause | Assignable Cause is a source of variation which is not due to chance and, therefore, can be identified and eliminated. An assignable cause is often signaled by an excessive number of data points outside a control limit and/or a non-random pattern within the control limits. Also called “special cause”. |

| Associativity | A link between two different functions in a CAD system that assures that a change made in one area is reflected in all other areas. For example, a change to a solid model will be reflected in its drawing and related CAM program. Bi-directional associativity indicates that updates happen in both directions between functions. For example, a change to a drawing will be reflected in its solids model. |

| ASSP | Application Specific Standard Part – a chip that is originally designed as an ASIC and is later released for general use. |

| ASTM | American Society for Testing and Materials |

| Asynchronous Groupware | Asynchronous Groupware is software used to help people to work in groups, but not requiring those people to be working together at the same time (asynchronous = not coordinating at a single point in time). |

| ATE | see Automated Test Equipment |

| ATP | Acceptance Test Procedure |

| ATPG | see Automatic Test Pattern Generation |

| ATS | Acceptance Test Specification |

| Automatic Test Equipment / Automated Test Equipment | Automated Test Equipment (ATE) built to perform a test or sequence of tests. ATE ranges from simple devices to verify mechanical or electrical continuity to sophisticated computerized systems with automatic sequencing, data processing, and readout. ATE may be stand alone test units or may be built into the operational equipment. |

| Automatic Test Pattern Generation | Automatic Test Pattern Generation is the process that utilizes lists of faults and a model of the circuit to analyze the logical and topical nature of the circuit in order to create test vectors for each fault and, thereby, produce a high-fault-coverage test pattern for a design. |

| Availability | The product metric that defines the percentage of time that a product is available and operational for customer use. It is the proportion of total time that an item of equipment is capable of performing its specified functions, normally expressed as a percentage. It can be calculated by dividing the equipment available hours by the total number of hours in any given period. |

| Axiomatic Design | Axiomatic Design recognizes four domains. The needs of the customer are identified in customer domain and are stated in the form of required functionality of a product in functional domain. Design parameters that satisfy the functional requirements are defined in physical domain, and, in process domain, manufacturing variables define how the product will be produced. Solution alternatives are created by mapping the requirements specified in one domain to a set of characteristic parameters in an adjacent domain. The mapping between the customer and functional domains is defined as concept design; the mapping between functional and physical domains is product design; the mapping between the physical and process domains corresponds to process design. The output of each domain evolves from abstract concepts to detailed information in a top-down or hierarchical manner. Two design axioms provide a rational basis for evaluation of proposed solution alternatives and the subsequent selection of the best alternative. The first axiom is the independent axiom, and it states that a good design maintains the independence of the functional requirements. The second axiom is the information axiom and it establishes information content as a relative measure for evaluating and comparing alternative solutions that satisfy the independence axiom. |

| Balanced Scorecard | A comprehensive performance measurement technique that considers four areas of performance in a balanced way: 1) customer perspective – how customers see us, 2) internal perspective – what we must excel at, 3) innovation & learning – how we continue to improve and create value, 4) financial perspective – how we meet shareholder needs. |

| Bath-Tub Curve | Bath-Tub Curve represents the failure rate of components over the life of the product. Its upward slope at the beginning and end suggests that most components fail either right away (at the beginning of the product life) or towards the end of the expected product life. |

| BCL | Binary Cutter Language |

| BEAR | see Break Even After Release |

| Behavioral Modeling | Behavioral Modeling defines a product in terms of required behaviors rather than relationships between geometry elements for mechanical products or relationships between components, gates and registers for electronic products. For example, the use of a hardware description language (see Hardware Description Language) is a means for describing a behavioral model for an electronic product. |

| Belief Map | The Belief Map is a method of graphically representing relative levels of knowledge and confidence. It is a plot whose horizontal axis represents the evaluator’s knowledge of, for example, a concept alternative’s ability to meet specified requirements. The vertical axis would represent the evaluator’s confidence in the concept’s ability to meet those requirements. |

| Benchmarking | An improvement process in which a company measures the performance of its products or processes against that of best-in-class products or companies, determines how the product or company achieved their performance level, and uses the information to improve its own performance. |

| Best Practice | Best Practice is a superior method or innovative practice that contributes to the improved performance of an organization, usually recognized as “best” by other peer organizations. |

| BET | see Breakeven Time |

| Beta Testing | Beta Testing is the testing a nearly-finished version of a piece of software or hardware, with the goal of finding defects missed by the developers. Often beta testing is carried out by people outside of the developers organization. |

| Bezier curve | Polynomial used to describe complex curves and surfaces. |

| BGA | Ball Grid Array – an electronic packaging technology in which solder balls are mounted to the underside of the package in a grid arrangement and are flowed for attachment to PCB’s. |

| Bill of Material | A Bill of Material (BOM) is a hierarchical list of subassemblies, components and/or raw materials that make up a higher-level component, assembly, product or system. An engineering BOM represents the assembly structure implied by the parts lists on drawings and drawing tree structure. A manufacturing BOM represents the assembly build-up the way a product is manufactured. |

| BIST | see Built-in-Self-Test |

| BIT | Built-in Test. See Built-in-Self-Test |

| Block Diagram | Block Diagram is a diagram that shows the operation, interrelationships and interdependencies of components in a system. Boxes or blocks represent the components; connecting lines between the blocks represent interfaces. |

| BMP | Best Manufacturing Practices |

| BOE | Basis of Estimate |

| BOM | see Bill of Material |

| Boundary Scan | A design for testability method that places a scan register at at every pin of every chip on a board for board testing and diagnostics. The test process can control and observe the state of every pin I/O pin without requiring physical access to any of them. |

| B&P | Bid and Proposal |

| BPI | Business Process Improvement |

| BPR | see Business Process Reengineering |

| Brainstorming | A creativity technique in which a group of people think of ideas related to a particular topic, listing as many possible ideas as possible before any critical evaluation of the ideas is performed. |

| Break Even After Release | Break Even After Release – a metric that measures the time after release of a product for production or sale until the the product has achieved financial breakeven considering the investment in development and other non-recurring expenses. |

| Break Even Time | Break Even Time – a metric that measures the time from the start of development through production and sales until the the product has achieved financial breakeven considering the investment in development and other non-recurring expenses. |

| B-Rep | Boundary Representation – solids modeling approach based on representing exterior surfaces that define a solid (as opposed to constructive solid geometry). |

| B-spline | A mathematical interpolation method for describing complex curves and surfaces |

| Built-in-Self-Test | Built-in-Self-Test – a feature of automatic testing where many test pattern programs are built directly into the circuit generally for go/no-go testing of the assembly or circuit using signature analysis. |

| Business Case | Business Case refers to the results of market, technical and financial analyses used to justify the feasibility of a new product. Ideally defined just prior to the “go to development” decision (gate), the case defines the product and project, including the project justification and the action or business plan. |

| Business Process Reengineering | Business Process Reengineering (BPR) is the analysis and redesign of workflow within and between enterprises. Authors Michael Hammer and James Champy promoted the idea of BPR as the radical redesign and reorganization of an enterprise to lower costs and increase quality of service. They suggested seven principles of reengineering to streamline the work process and thereby achieve significant levels of improvement in quality, time management, and cost: 1) organize around outcomes, not tasks; 2)identify all the processes in an organization and prioritize them in order of redesign urgency; 3) integrate information processing work into the real work that produces the information; 4) geographically dispersed resources as though they were centralized; 5) link parallel activities in the workflow instead of just integrating their results; 6) put the decision point where the work is performed, and build control into the process; and 7) capture information once and at the source. |

| CAD | see Computer-Aided Design |

| CAD Framework Initiative | CAD Framework Initiative – a standard to facilitate integration of electronic design automation (EDA) tools This allows an organization to select “best of class” tools without worrying about integration issues. The CFI standards cover Design Representation Programming Interface, the Intertool Communication Programming Interface, the Tools Encapsulation Specification, the Computing Environment Services. |

| CAE | see Computer-Aided Engineering |

| CAGR | Compound Annual Growth Rate |

| CAI | Computer-Aided Inspection |

| CAIT | Computer-Aided Inspection and Test |

| CAIV | see Cost as an Independent Variable (DoD initiative) |

| CAM | 1. see Computer-Aided Manufacturing 2. Cost Account Manager |

| Capability | Capability is a measure of the ability of a system to perform within its specification limits. It uses a series of indices: Cp, Cpk, Cr, and Cpm. |

| Capability Maturity Model | Capability Maturity Model (CMM) is a model of five levels of process maturity developed by the Software Engineering Institute (SEI) a Carnegie-Mellon University for software development processes. These five levels starting at level one are: ad-hoc, repeatable, defined, managed and optimized. See Product Development Capability Maturity Model for our adaptation of the CMM to product development. |

| CAPP | see Computer-Aided Process Planning |

| CASE | 1. see Computer-Aided Software Engineering 2. Computer-Aided Systems Engineering |

| CAT | Computer-Aided Test |

| CCA | Circuit Card Assembly |

| Cell | 1. An individual component of a technology library. Typically a logic gate (for example, a 2-input NAND gate). 2. Manufacturing cell is a grouping of equipment to perform the required processing for a part of assembly. |

| Commercialization | Commercialization is the process to taking a new product from development to full volume sales. It includes steps such as testing and market validation, production launch and ramp-up, development of marketing programs and materials, supply chain development, sales channel development, training development, training, and service and support development. |

| CCB | 1. Change Control Board 2. Configuration Control Board |

| CCD | Configuration Control Drawing |

| CCM | see Critical Chain Method |

| CCPM | Critical Chain Project Management. see Critical Chain Method |

| CDR | Critical Design Review |

| CDRL | Contract Data Requirements List |

| CE | 1. see Concurrent Engineering 2. Chief Engineer 3. Concept Exploration 4. Concept Engineering |

| CER | Cost Estimating Relationship |

| Certification | 1. A process, which may be incremental, by which a contractor provides evidence to the acquirer that a product meets contractual or otherwise specified requirements. 2. The approval by a regulatory or standards body that a product meets the applicable requirements or standards. |

| CFD | see Computational Fluid Dynamics |

| CFI | see CAD Framework Initiative |

| CFT | see Cross-Functional Team |

| Change Management | Change Management is a systematic approach to dealing with change, both from the perspective of an organization and on the individual level. Change management has at least three different aspects including: adapting to change, controlling change, and effecting change. A proactive approach to dealing with change is at the core of all three aspects. For an organization, change management means defining and implementing procedures and/or technologies to deal with changes in the business environment and to profit from changing opportunities. |

| Charter | Charter is a written commitment approved by management stating the scope of authority for a development project or integrated product team. |

| Check-In | The process of placing or returning a new or modified product information under control within a PDM/PIM system. If a revision is being created, this procedure usually initiates a review/approval process under control of the PDM/PIM system. |

| Check-Out | The process of accessing managed product definition information under controlled procedures. Access may be for viewing, reference, for use in another application or task, or for making a change to the information. The PDM/PIM system prevents multiple, simultaneous change activities to ensure product information integrity. |

| Chip-on-Board | Chip-on-Board is a component packaging technology in which bare integrated circuits are attached directly to the substrate and interconnected by means of microscopic wires. |

| CI | 1. Continuous Improvement 2. see Configuration Item |

| CIM | Computer-Integrated Manufacturing |

| CIME | Computer-Integrated Manufacturing and Engineering |

| CITIS | Contractor Integrated Technical Information Services (CALS initiative) |

| Classification | Classification is the assignment of attributes and other defining meta-data to managed objects and information within a PDM system. This meta-data are then used for finding data with similar characteristics. |

| Clinical Trial | Clinical Trial is testing a system in a clinical setting; that is, in a hospital, clinic, doctor’s office, etc. User testing and feature testing in such an environment has special limitations, especially because of the potential for unexpected effects on patient care. User testing in clinical settings will often require review by an ethics committee to ensure that patient privacy is not compromised and that no harm will come to patients as a result of testing. As with drug testing, it may not be appropriate to remove a feature from a system for the sake of testing if it appears that the feature is directly benefiting patient care. |

| Cloud of Points | A set of x-y-z coordinates obtained from a 3D scanner or digitizer. The data can be interpreted as a continuous surface and used in a 3D model. This is often used for reverse engineering. |

| CM | see Configuration Management |

| CMM | 1. see Coordinate Measuring Machine 2. see Capability Maturity Model |

| CNC | Computer Numerical Control |

| CND | Cannot Duplicate (failures). Also known as “No Trouble Found” (NTF) |

| COB | see Chip-on-Board |

| Cognitive Modeling | Cognitive Modeling produces a computational model for how people perform tasks and solve problems, based on psychological principles. These models may be outlines of tasks written on paper or computer programs which enable us to predict the time it takes for people to perform tasks, the kinds of errors they make, the decisions they make, or what buttons and menu items they choose. Such models can be used to determine ways of improving the user interface so that a person’s task has fewer errors or takes less time and to build into the user interface to make software that reacts more effectively to help people use the system by anticipating their behavior. |

| Cognitive Walkthroughs | Cognitive walkthroughs involve the development of task scenarios from a product specification. Experts then role-play the part of a user working through a set of tasks. Each step of the user’s process is evaluated for adherence to established usability principles. |

| Collaboration | 1. Working together, cooperating 2. A process of maximizing both cooperative and assertive behavior to satisfy two parties in conflict with one another. |

| Collaborative Product Commerce | The Aberdeen Group defines Collaborative Product Commerce (CPC) as “…a class of software and services that uses Internet technologies to permit individuals – no matter what role they have in the commercialization of a product, no matter what computer-based tools they use, no matter where they are located geographically or within the supply net – to collaboratively develop, build, and manage products throughout the entire lifecycle. Using a standard browser, an authorized CPC user can review information from an extended-enterprise information system ‘view’ that operates across a dispersed set of heterogeneous product development resources. These resources typically reside in multiple information repositories and are derived from independently implemented and maintained systems.” |

| Collocation | The practice of physically locating multi-function integrated product team members in proximity to one another to enhance communication, coordination and decision-making on a development project. Virtual collocation refers to the use of technology to achieve some of the communication benefits for team members that are geographically dispersed. |

| Common Cause | Common Cause is a variation that is inherent in the process and cannot be readily identified and controlled. |

| Competitive Intelligence | Methods and activities for transforming disaggregated public competitor information into relevant and strategic knowledge about competitors’ position, size, efforts and trends. The term refers to the broad practice of collecting, analyzing, and communicating the best available information on competitive trends occurring outside one’s own company. |

| Component Engineering | The application of engineering know-how to the processes of component selection, application, process compatibility and procurement, including analysis of new trends in electronic devices. |

| Component Supplier Management | Component Supplier Management (CSM) is a class of software applications that maintain information about standard components, both purchased and made, to support various functional disciplines such as design, procurement, materials, configuration management, and manufacturing. This system serves as a central repository for component and supplier information to maximize standardization, design retrieval and re-use, and procurement efficiency. CSM systems contain four major elements, part classification and retrieval, component libraries, Web component cataloging, and component/supplier process management. |

| Computational Fluid Dynamics | Computational Fluid Dynamics is the numerical analysis of fluid and gas flow, heat transfer, and related phenomena. CFD solvers contain a complex set of algorithms used for modeling and simulating the flow of fluids, gases, heat, and electric currents. |

| Computer-Aided Design | Computer-Aided Design (CAD) is the use of a computer to assist in the creation and modification of a design, most commonly, designs with a heavy engineering content. |

| Computer-Aided Engineering | Computer-Aided Engineering (CAE) is the use of computers in design, analysis, and manufacturing of a product, process, or project. Sometimes refers more narrowly to the use of computers only in the analysis stage. |

| Computer-Aided Manufacturing | Computer-Aided Manufacturing (CAM) is the use of the computer description of the part or assembly to drive planning, cutting, forming, assembly and inspection of the item via computerized applications. |

| Computer-Aided Process Planning | Computer-Aided Process Planning uses part data and process rules to generate process plans or work instructions. Variant CAPP is based on group technology classification of parts and part features to search for a predetermined similar process plan that most closely matches the classification. Generative CAPP uses part and feature classification along with rules and knowledge about manufacturing processes associated with features to generate an appropriate process plan. |

| Computer-Aided Software Engineering | Computer-Aided Software Engineering (CASE) is the application of computer technology to facilitate the development of software. CASE tools usually include libraries of reusable code (modules of software that can be easily modified for specific tasks), programmer productivity tools, application generators, and testing utilities. CASE tools also provide requirement management, structured system design and analysis, system simulation, test management, documentation generation, etc. |

| Computer Software Configuration Item | Computer Software Configuration Item (CSCI) is a software component of a system, which is designated for configuration management to ensure configuration integrity. It may exist at any level in the hierarchy where interchangeability is required. Each CSCI is to have (as appropriate) individual design reviews, individual qualification/certification, individual acceptance reviews, and separate user manuals. |

| Concept | An idea for a new product or system that is represented in the form of a written description, a sketch, block diagram or simple model. A concept is the earliest representation of a new product or of alternative approaches to designing a new product. |

| Concept Model | A physical model or representation intended primarily for design review, product conceptualization and customer feedback. This model is usually not sufficiently accurate or durable for full functional and physical testing. |

| Concept Testing | The process by which a concept statement, sketch or model is presented to customers for their reactions. These reactions can either be used to permit the developer to estimate the sales value of the concept or to make changes to the concept to enhance its potential sales value. |

| Conceptual Architecture | The Conceptual Architecture represents an appropriate decomposition of the system without delving into the details of interface specification. The conceptual architecture identifies the system components or subsystems, the responsibilities of each component or subsystem, and interconnections between components or subsystems. |

| Concurrency | The degree to which phases, stages, or activities may be overlapped or done in parallel. |

| Concurrent Engineering | A systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support. This approach is intended to cause the developers, from the outset, to consider all elements of the product life cycle from conception through disposal, including quality, cost, schedule and user requirements. |

| Configuration | A collection of an item’s descriptive and governing characteristics, which can be expressed in a) functional terms, i.e. what performance the item is expected to achieve, and b) physical terms, i.e. what the item should look like and consist of when it is completed. |

| Configuration Item | Configuration Item (CI) is a hardware, software, or composite item that has a defined function, can be at any level in the system hierarchy, and is designated for configuration management. |

| Configuration Management | Configuration Management (CM) is the process of managing a product’s requirements and design documentation as it evolves and changes over its lifecycle (from requirements definition through production, operation, support and disposal) and assuring that the resulting products and processes conform to this documentation. Configuration Management function’s include maintaining the configuration status of a document, product and process; reporting on this configuration; controlling changes to this configuration; (see Engineering Change Control), and verifying that the resulting configuration of the product or process corresponds with that intended in its underlying documentation. |

| Conformance Testing |

The testing of a candidate product for the existence of specific characteristics required by a standard in order to determine the extent to which that product is a conforming implementation. |

| Conjoint Analysis | A methodology for exploring and describing subjective customer views of product features. Conjoint analysis avoids direct questioning, e.g., “what do you think of the price of our product?” Instead, the customer is asked what they are willing to pay for a particular product feature. Thus, the real buying situation with consideration of different cost-benefit alternatives is simulated. The resulting analysis show directly the contribution of each product feature to the total product utility. Conjoint analysis can be used to determine to what extent a product’s perceived utility changes if some particular product feature is modified. |

| Consensus | Consensus is a group decision resulting from members engaging in full and open discussion and then reaching agreement to live with and openly support the resulting decision. |

| Constraints | 1. As related to CAD, these are values in a geometric model that define relationships between entities such as planes, surfaces, points, lines, arcs, centers, edges, etc. Constraints are used to fully define a model and to drive parametric or variational geometry systems. The algorithms used to work with constraints are known as constraint management 2. Restrictions or boundaries impacting overall capability, priority, and resources. |

| Contextual Analysis / Contextual Inquiry | Contextual Analysis / Contextual Inquiry is a structured field evaluation method which uses a combination of methodologies derived from anthropology and journalism. By observing and interviewing users of products in their actual environment and understanding the context in which a product is used, better insight is gained into the issues that affect contextual analysis / contextual inquiry is a discovery process that can add insight into the needs of customers. |

| Contingency | A Contingency is the planned allotment of time, cost, budget or design margin for unforeseeable elements or risks with a development project. |

| Contingency Design | Contingency Design is a form of mistake-proofing focusing on the user’s experience with the product. The intent is to design in features that help the user avoid mistakes or allow the users to quickly correct input of data or operation of the product. This is accomplished through layout and graphic design, intuitive operation, clear instructions, appropriate markings and warnings, descriptive error messages, avoidance of technical jargon, and simple operation steps. |

| Control Chart | A graphical display of results of a process over time. They are used to determine if a process is in statistical control or in need of adjustment. |

| Control Limits | In statistical process control (SPC), two horizontal lines are drawn on a control chart denoting the upper control limit (UCL) and the lower control limit (LCL). The sample-means and the ranges from a production lot must be within these limits. If they are so, the process is behaving normally and is said to be under control. If any point lies outside either of the limits, this denotes loss of control – the process must be halted and the reason found. |

| Control Plans | Control Plans are written descriptions of the systems for controlling parts, assemblies, products, and processes. They are written to address the important characteristics and engineering requirements of the product. Each part or assembly should have a Control Plan, but in many cases, “family” Control Plans can cover a number of parts produced using a common process. |

| Cooperative Design | see Participatory Design |

| Coordinate Measuring Machine | Coordinate Measuring Machine (CMM) is a device that dimensionally measures 3-D products, tools and components with an accuracy approaching 0.0001 in. It used for both inspection and reverse engineering. |

| COQ | see Cost of Quality |

| Core Competencies | Core Competencies are the essential capabilities that create a firm’s sustainable competitive advantage. |

| Corrective Action | Corrective Action is an action taken to eliminate the causes of an existing nonconformity or other undesirable situation in order to prevent recurrence. |

| Cost as an Independent Variable | Cost as an Independent Variable (DoD initiative) – an acquisition strategy of obtaining the best available product/system within the constraints of available resources. Cost performance and schedule trades are made to achieve this balance with budget. |

| Cost Benefit Ratio | The ratio of the present value of benefits to the present value of costs. |

| Cost Drivers | 1. Those elements of cost which significantly impact the product/system’s cost. 2. Any factor that causes a change in the cost on an activity. An activity may have multiple cost drivers associated with it. |

| Cost Estimating Relationship | Cost Estimating Relationship is an equation that defines the relationship of an independent variable or product parameter (e.g., product weight, speed, etc.) to its related cost or price. Cost estimating relationships are the basis of parametric cost estimating techniques. |

| Cost Model | A Cost Model is an estimating tool consisting of one or more cost estimating relationships, estimating methodologies, or estimating techniques used to predict the cost of a system or one of its lower level elements. |

| Cost of Quality | All costs expended for appraisal costs, prevention costs, and both internal and external failure costs of activities and cost objects. |

| Cost Reduction | A formal activity employed to rectify a cost target breach or to reduce the cost of an existing product or design. A cost reduction effort has a specific quantified objective and may affect schedule, performance or support to achieve this objective. |

| Cost Table | A Cost Table is a multidimensional data base in which cost is captured for several levels of a number of attributes for either the parts or functions of a product. Cost tables are used to develop early estimates of the cost of a design based on product or part parameters or functions and different materials and manufacturing processes and methods. Cost tables have been primarily used by Japanese companies. |

| COTS | Commercial Off-The-Shelf |

| Cp | Cp is a capability index that tells how well a system can meet two-sided specification limits, assuming that the average is centered on the target value. Cp is the ratio of the specification range to the process capability at plus or minus 3 sigma. |

| CPC | see Collaborative Product Commerce |

| CPD | Concurrent Product Development (Synonymous with concurrent engineering or integrated product development. See Integrated Product Development) |

| CPLD | Complex Programmable Logic Device – contains more than 1,000 gates and 44 or more pins. |

| CPI | Continuous Process Improvement |

| Cpk | Cpk is a capability index for a non-centered mean that tells how well a system can meet two-sided specification limits. Cpk is the ratio of the specification range to the process capability at plus or minus 3 sigma. |

| CPM | Critical Path Method – A method for determining the minimum project duration by identifying the critical path based on task interrelationships and duration. It assumes there is no wasted time for the activities that are on the critical path. |

| Crashing | Taking action to decrease the total project duration by analyzing a number of alternatives to determine how to get the maximum duration compression for the least cost. Often, it involves reducing the time it takes to complete an activity by adding resources. |

| Creeping Elegance / Featurism | The tendency for designers to add more capability, functions and features to a product as it is being developed than were originally intended. These actions cause a product’s cost to increase beyond the target, the schedule to slip and can detract from usability. |

| Critical Chain Method | Critical Chain Method is a project scheduling and management methodology developed by Eliyahu Goldratt based on concepts from the Theory of Constraints. With Critical Chain scheduling, uncertainty is primarily managed by (a) using average task duration estimates; (b) scheduling backwards from the date a project is needed (to ensure work that needs to be done is done, and it is done only when needed); (c) placing aggregate buffers in the project plan to protect the entire project and the key tasks; and (d) using buffer management to control the plan. |

| Critical Characteristics | The characteristics or specifications for a material, part, assembly or product that define those attributes that are essential to the proper fit or functioning of the item to satisfy the intended customer use or need. |

| Critical Path | In a project network diagram, the critical path is the one with the longest duration. The critical path may change from time to time as activities are completed ahead of or behind schedule. (see CPM) |

| Critical-to-Function (CTF) | A subset of drawing/model parameters that are critical to function and have tolerances and/or datums different from the standard tolerances or datum. As a result, these parameters will usually have tolerances and datums specifically defined on a drawing or in a model. In the absence of dimensional drawings, CTF dimensions are a means of communicating dimensions critical to success of the design, tolerance and other non-geometrical information. This approach is generally simpler than a complete fabrication drawing because of fewer dimensions. |

| Critical to Quality | Critical to Quality (CTQ) characteristics are the key measurable characteristics of a product or process whose performance standards or specification limits must be met in order to satisfy the customer. They align improvement or design efforts with customer requirements. Also see critical characteristics. |

| Cross-Functional Team | Cross-Functional Team is a team consisting of representatives from marketing, engineering, manufacturing, finance. purchasing, test, quality, finance and any other required disciplines with responsibility for developing a product or product subsystem. This team is empowered to represent the functional disciplines and develop a product by addressing its life cycle requirements including its product and support. |

| CSCI | see Computer Software Configuration Item |

| C/SCS | Cost/Schedule Control System is a performance measurement system that uses earned value techniques to breakdown a budget to cost variation into cost and schedule variation components |

| CSG | Constructive Solids Geometry – a solid modeling method using primitives to build more complex models and Boolean operations of add, difference, and intersection. |

| CSM | see Component Supplier Management |

| CTF | see Critical-to-Function |

| Cumulative Tolerance | Progressive accumulation of tolerances resulting from multiple operations or assembly of multiple parts. |

| Customer Need | A fundamental need to be satisfied independent of a particular technology or product solution (e.g., access the internet.) |

| Data Dictionary | Data Dictionary – a definition of data elements for uses such as information engineering or quality function deployment. |

| Data Flow Diagram | Data Flow Diagram a structured system design representation of processes and the data flows that connect the processes. |

| Data Interchange | Data Interchange refers to the ability to exchange and use product data between various types of CAD/CAM/CAE systems. Data interchange can be accomplished by (listed in order of maximum interchange of product model intent): use of the same CAD system, use of the same CAD kernel (e.g., ACIS, parasolid, etc.), dedicated translator between two CAD systems, and use of neutral file formats (e.g., STEP, IGES, etc.). |

| Datum | Theoretically exact planes, lines or points from which other features are located on design drawings. |

| DBF | Design by Features |

| DBT | Design Build Team – term used by Boeing and others synonymous with integrated product team. A multi-function or cross-functional team with responsibilities for requirements definition, product and process design, and production launch of a new product. |

| DCF | see Discounted Cash Flow |

| Decomposition | Decomposition is the process of dividing the system into its smallest, coherent, self-contained elements. Decomposition is used in systems engineering, software engineering, process mapping and functional analysis system technique. |

| Defects Per Million Opportunities | Defects Per Million Opportunities (DPMO) is a quality measurement where defects are defined as material or process or related, and opportunities for defects are defined as the sum of all parts, lead attachments and/or glue dots as applicable for each part number assembled |

| Defect Tracking | Defect Tracking typically refers to identifying flaws appearing during manufacturing. The goal is not only to spot defects but to track them and identify the source of the problem to prevent them. Were specs incomplete, impractical, or poorly specified? Was the design difficult to produce? Were needed process capabilities lacking? |

| Derived Requirements | Requirements that are not explicitly stated in the customer requirements, but are inferred a) from contextual requirements (e.g., applicable standards, laws, policies, common practices, and management decisions), or b) from requirements needed to specify a product component. Derived requirements can also arise during analysis and design of components of the product or system. |

| Design Failure Modes and Effects Analysis | Design Failure Modes and Effects Analysis (DFMEA) – a form of FMEA associated with the product design (see Failure Modes and Effects Analysis). |

| Design for Assembly | Design for Assembly (DFA) refers to the principles of designing assemblies so that they are more manufacturable. DFA principles address general part size and geometry for handling and orientation, features to facilitate insertion, assembly orientation for part insertion and fastening, fastening principles, etc. The objective of DFA is to reduce manufacturing effort and cost related to assembly processes. |

| Design for Disassembly | Design for Disassembly (DFD) is a set of principles used to guide designers in designing products that are easy to disassemble for recycling, remanufacturing, or servicing. |

| Design for Environment | Design for Environment is a process for the systematic consideration during design of issues associated with environmental safety and health over the entire product life cycle. DFE can be thought of as the migration of traditional pollution prevention concepts upstream into the development phase of products before production and use. |

| Design for Manufacturability | 1. Design for Manufacturability (broad definition) is a methodology for designing product’s in a way that facilitates the fabrication of the product’s components and their assembly into the overall product. In this respect it is synonymous with Design for Manufacturability / Assembly. 2. Design for Manufacturability (narrow definition) is a methodology for designing product’s components in a way that facilitates their fabrication. |

| Design for Manufacturability / Assembly | Design for Manufacturability / Assembly (DFM/A) is the broad definition of optimizing a product’s design for make it’s parts more manufacturable (fabrication) and easier to assemble. DFM/A includes: understanding the organization’s process capabilities, obtaining early manufacturing involvement, using formalized DFM/A guidelines, using DFM/A analysis tools, and addressing DFM/A as part of formal design reviews. |

| Design for Postponement | With a product that offers a lot of different configurations and options, an objective is to delay of postpone the assembly of the unique parts or subassemblies into the product until as late as possible in the final assembly process. This reduces production leadtime (products can be built and stocked up to this point), facilitates a strategy of mass customization, and provides supply chain flexibility. Design for postponement is the design of an assembly in a way that allows the customizable parts of the product to be assembled as late as possible in the assembly process. |

| Design For Reliability | Design For Reliability (DFR) is methodology and set of principles to enhance product reliability and reduce overall low life-cycle costs. It is based on early involvement of reliability engineering working with design engineering to enhance reliability by performing steps such as the following: reliability program planning, reliability predictions, parts derating, thermal analysis, failure modes and effects analysis (FMEA), fault tree analysis (FTA), availability and system modeling, HALT/HASS, design verification testing, product return rate analysis, FRACAS, and root cause failure analysis. |

| Design for Serviceability | Design for Serviceability (DFS) is a set of principles and a methodology for analyzing product concepts or designs for characteristics and design features which reduce service requirements and frequency, facilitate diagnosis, and minimize the time and effort to disassemble, repair/replace, and reassemble the product as part of the service process. |

| Design for Six Sigma | Design for Six Sigma (DFSS) is a systematic methodology or quality framework utilizing tools, processes and measurements to enable the design of products and processes that meet customer expectations and can be produced at Six Sigma quality levels. DFSS is built around five connected phases of Define, Measure, Analyze, Design, Verify or DMADV. The tools and methods to support DFSS include voice of the customer (VOC), quality function deployment (QFD), design for manufacturability and assembly, design of experiments (DOE), failure mode and effects analysis (FMEA), process capability studies, design reviews, control plans, etc. |

| Design Intent | The intended form, fit, function, and characteristics of a product or its constituent parts. |

| Design of Experiments | A statistical methodology for designing, conducting and analyzing experiments or tests to evaluate product and process design parameters or factors that affect the achievement of a product performance characteristic. The response of interest is evaluated under the various conditions to: (1) identify the influential variables among the ones tested, (2) quantify the effects across the range represented by the levels of the variables, (3) gain a better understanding of the nature of the causal system at work in the process, and (4) compare the effects and interactions. These experiments lead to setting parameter or factor levels (values) that can optimize the product performance characteristic under study and minimize the affects of variation. There are several techniques including Taguchi Methods, fractional factorial, and Plackett-Burman. DOE’s are often classified in one of three categories: Screening Designs, which are intended to identify which main effects (factors) are the vital few important factors that require further study (usually a fractional factorial); Characterization Designs, which are used to gain some quantitative understanding of the relationships among the factors, including interactions, on the response variable (usually a factorial); and Optimization Designs, which are used to gain a precise understanding of the mathematical relationships that is sufficient to allow prediction and optimization throughput the experimental region. |

| Design Optimization | 1. Design Optimization in the broad sense refers to optimizing a design to meet its functional, environmental and lifecycle requirements at a minimum of cost. 2. Design Optimization in a narrower sense refers to the use of computer-aided engineering applications which analyze a design and, given constraints and objectives, seek to improve or optimize the design to meet the stated objectives within the stated constraints. These applications will typically use an iterative, goal-seeking cycle to seek design optimization. |

| Design Reviews | Design reviews are formal technical reviews conducted during the development of a product to assure that the requirements, concept, product or process satisfies the requirements of that stage of development, the design is sound, the issues are understood, the risks are being managed, any problems are identified, and needed solutions proposed. Typical design reviews include: requirements review, concept/preliminary design review, final design review, and a production readiness/launch review. |

| Design Structure Matrix | Design Structure Matrix – matrix used to represent and analyze task dependencies in a product development project / process. |

| Design-to-Cost | A development methodology that treats cost as an independent design parameter. A realistic cost objective is established based on customer affordability, tradeoff’s are made between the cost objective and other product functions/parameters, cost models are used to project the cost early in the development cycle, and a variety of techniques such as function analysis and DFM are used to proactively achieve the cost objective. |

| Design to Life-Cycle Cost | This represents the totality of design-to-cost addressing all costs related to acquisition, operation, support and disposal. |

| Design to Unit Production Costs | The average unit production costs for producing the specified hardware lot(s) which generally includes recurring material, labor and overhead costs; engineering change costs; program management costs; and production support costs. |

| Design Validation | Testing to assure that the product conforms to defined user needs and requirements. This normally occurs toward the end of the Design Phase following successful design verification and prior to pilot production, beta/market testing, and product launch. Design validation is normally performed on the final product under defined, operating conditions. Multiple validations may be performed if there are different intended uses. See Validation. |

| Design Verification | Design verification is the process of ensuring the design conforms to specification (design outputs meet design input requirements). Design verification may include: alternate calculations, design reviews, comparison to similar designs, inspection, and system or product testing. |

| Detailed Design | The conversion of product specifications into designs and their associated process and/or code-to documentation. Detailed design includes design capture, modeling, analysis, developmental testing, documentation, process design, producibility analysis, test plan development, coding, and design verification and validation. |

| Deterministic | An approach that presumes the presence of fixed constraints. |

| DFA | see Design for Assembly |

| DFAA | Design for Automated Assembly |

| DFD | 1. see Design for Disassembly 2. see Data Flow Diagram |

| DFE | see Design for the Environment |

| DFM | see Design for Manufacturability |

| DFM/A | see Design for Manufacturability / Assembly |

| DFMEA | see Design Failure Modes and Effects Analysis |

| DFMt | Design for Maintainability |

| DFSS | see Design for Six Sigma |

| DFT | Design for Test |

| DFX | Design for Excellence – designing to consider all relevant life cycle factors such as manufacturability, reliability, maintainability, testability, affordability, etc. |

| Diagnosability | The ability to uniquely identify any faults (or potential faults) in the behavior or operation of the product. Diagnosability would indicate not only what the fault was, but also what failed or caused the failure (e.g., module, component, line of code, etc.). |

| Digital Mock-up | Solids modeling capabilities that enable complete products to be built in electronic form. The mockups can be used to check for problems such as interference and clashes between components. Using digital mockups reduces the cost and time of development since physical models do not need to be built. Synonymous with digital pre-assembly, electronic mock-up, and assembly modeling. |

| Direct Costs | Cost that can be specifically identified or traced to an activity, cost object or final cost objective. |

| Direct Digital Manufacturing | The process of going directly from an electronic digital representation of a part or item to the final part or item via additive fabrication. See Additive Fabrication. |

| Directed Evolution | Directed Evolution is an advanced TRIZ methodology used to create scenarios to support the planning and development of future generations of technical systems. |

| DIS | Draft International Standards (International Standards Organization) |

| Discontinuous Innovation | Discontinuous innovation falls outside of existing markets or market segments, and when successful extends and redefines the market, exposing new possibilities. Discontinuous innovation is characterized by lateral or divergent thinking, by looking outside of defined boundaries, and by discovery of new knowledge related to both market need and technological capability. |

| Discounted Cash Flow | Discounted Cash Flow – an analysis technique that determines the present value of a series of positive and negative cash flows using a specified discount factor representing the cost of capital. This can be used to compare investment alternatives such a new product development alternatives. |

| DMAIC | Define, Measure, Analyze, Improve and Control – a Six Sigma improvement methodology |

| DMADV | DMADV is a data driven quality strategy for designing products and processes that is an integral part of a Six Sigma quality initiative. It consists of five interconnected phases: define, measure, analyze, design and verify. |

| DMIS | Dimensional Measurement Interface Specification (ANSI standard) |

| DNC | Distributed Numerical Control |

| DOA | Dead on Arrival. Products that don’t operate when received and first used by a customer. |

| DoD | Department of Defense |

| DOE | 1. see Design of Experiments 2. Department of Energy |

| DPA | Digital Pre-Assembly – a term for electronic mock-up performed with CAD solids modeling. |

| DPM | Defects per Million |

| DPMO | see Defects Per Million Opportunities |

| DRM | 1. Drawing Requirements Manual 2. Drafting Room Manual 3. DRM Associates (product development consulting and training firm) |

| DSM | 1. Deep Sub-Micron design – relates to the design of integrated circuits with feature sizes less than .5um. 2. see Design Structure Matrix |

| DSS | Decision Support System |

| DTC | Design to Cost is a development methodology that treats cost as a design parameter. A realistic cost objective is established based on customer affordability, cost models are used to project the cost early in the development cycle, and a variety of techniques such as value analysis and DFM are used to proactively achieve the cost objective. |

| DTLCC | Design to Life Cycle Cost |

| Durability | The probability that an item will continue to function at customer expectation levels at the useful life without requiring overhaul or rebuild due to wear-out. |

| DTUPC | see Design to Unit Production Cost |

| Durability | The ability of a product and any of its components to perform the required functions in its intended service environment over its intended service life without unforeseen cost of maintenance and repair. |

| DUT | Device Under Test |

| DXF | Data Exchange Format – format for CAD drawings often used to transfer CAD data from one system or program to another. |

| Dynamic Analysis | Dynamic Analysis is the analysis of mechanism’s motions that result from forces. Dynamic simulation is more complex than Kinematic Analysis because the problem needs to be further defined and more data is needed to account for the forces. But Dynamic Analysis is often required to accurately simulate the actual motion of a mechanical system. Generally, Kinematic Analysis helps evaluate form, while Dynamic Analysis assists in analyzing function. (Also see Kinematic Analysis.) |

| EAC | Estimate at Completion |

| Early Adopter | Early Adopter is a person or organization who chooses to purchase or use relatively new technology before it is fully embraced by the mass market. Early adopters are therefore people or organizations who have a stronger need for the technology, a lower reluctance to use it, or the ability to overcome barriers to adopting it. |

| Early Supplier Involvement | Early Supplier Involvement is the process of getting the supplier involved early in the development process (when an item is being conceptualized, designed or specified) so that the supplier can make proactive suggestions to improve the design and reduce its cost vs. providing reactive feedback once the design has been completed. |

| EC | 1. Engineering Change 2. Electronic Commerce 3. European Community |

| ECAD | Electrical/Electronic Computer-Aided Design |

| ECAE | Electrical/Electronic Computer-Aided Engineering |

| ECCB | Electronic Component Certification Board |

| ECN/ECO | see Engineering Change Notice / Engineering Change Order |

| ECP | Engineering Change Proposal |

| EDA | see Electronic Design Automation |

| EDB | Electronic Data Book |

| EDI | Electronic Data Interchange (ANSI-X.12) – EDI is the exchange, between organizational entities, of computer processable data in a standard format. The 841 transaction is used to transfer technical data. |

| EDIA | Electronic Data Interchange Association |

| EDIF | see Electronic Design Interchange Format |

| EDM | 1. Engineering Data Management 2. Engineering Document Management 3. Electronic Document Management 4. Electrical Discharge Machining |

| EDMS | 1. Electronic Document Management System 2. Engineering Data Management System |

| EEPROM | Erasable Programmable Read Only Memory |

| Effectivity | An indicator in a product structure which specifies the versions at which a component part is used. These indicators generally specify a range of either dates, serial numbers, or build lots. Effectivity indicators are typically considered as ‘conditions’ on the parent-child relationships in a product structure. |

| Effectivity Date | Effectivity Date is the date from which an intended engineering change is to come into effect (new product configuration) or the past configuration of the product is to go out of effect. |

| EIA | Electronic Industries Association |

| EIS | 1. Engineering Information System 2. Executive Information System |

| Electronic Design Automation | Electronic Design Automation (EDA) consists of hardware and software tools to aid in the design and development of electronic products through design capture, simulation, synthesis, verification, analysis, and testing. |

| Electronic Design Interchange Format | An EIA/ANSI standard which defines the file format for communicating two-dimensional graphics and interconnection information that is used to describe the patterns for fabricating and manufacturing semiconductors and PCB/PWB’s. |

| Electronic Manufacturing Services | Electronic Manufacturing Services (EMS) refers to the industry that provides contract design, manufacturing, and related product support services on behalf of electronics OEMs, in which the design and brand name belongs to the OEM making electronic products or subassemblies to be sold under the OEM brand name. Often referred to as “Contract Manufacturing” or “Contract Electronics Manufacturing”. |

| Electronic Systems Design Automation | Electronic Systems Design Automation (ESDA) is a set of graphical front-end tools that allow designers to use pictures rather than words to describe and analyze their creations. These tools can use HDL’s as an interchange format rather than a design medium and allow for higher degrees of abstraction over traditional schematic capture or waveform display programs. |

| Electronic Systems Level | Electronic Systems Level is a higher level abstraction for the design of electronic products than RTL (see Register Transfer Level) which will improve design productivity with the design of ever larger and more complex electronic systems. This is the third generation in design methodologies and tools (gate-level, register transfer level, and electronic systems level). Key elements of ESL include behavioral synthesis, integration between the behavioral level and the architecture level, and hardware/software codesign and coverification. |

| EMI | 1. Early Manufacturing Involvement 2. Electro-Magnetic Interference |

| Empathic Design | Empathic Design is based on observation — watching customers/consumers use products or services. But unlike focus groups, usability laboratories, and other contexts of traditional market research, this observation is conducted in the customer’s own environment in the course of normal, everyday routines. This approach enables the researcher to observe and develop information on customer needs that will drive design that is not accessible through other observation-oriented research methods. |

| EMS | see Electronic Manufacturing Services |

| Emulation | The process by which a device under development and its native software is prototyped before its manufacture. |

| End-of-Life | End-of-Life (EOL) is the term applied to products or components that are being retired from the market because of technology obsolescence or rapidly declining demand. |

| Engineering Change |

A modification to a component, product configuration, or document from currently defined and approved status. Changes cause version or revision levels of affected items to be updated. |

| Engineering Change Control | Engineering Change Control is the process and procedures that manage how changes are proposed, reviewed, and approved and incorporated into a product and its associated data items. Change control is a part of an overall configuration management methodology and uses review and release processes to enforce compliance with company change policies. |

| Engineering Change Notice / Engineering Change Order | Engineering Change Notice (ECN) / Engineering Change Order (ECO) are formal documents notifying selected persons of proposed, pending, or accomplished changes. In a PDM/PIM-managed environment, ECNs may be distributed by electronic mail. |

| Enhanced Quality Function Deployment | Enhanced Quality Function Deployment is a broader QFD framework that applies a system perspective recognizing the need to decompose more complex products into subsystems and assemblies with supporting deployment matrices and concept selection matrices. |

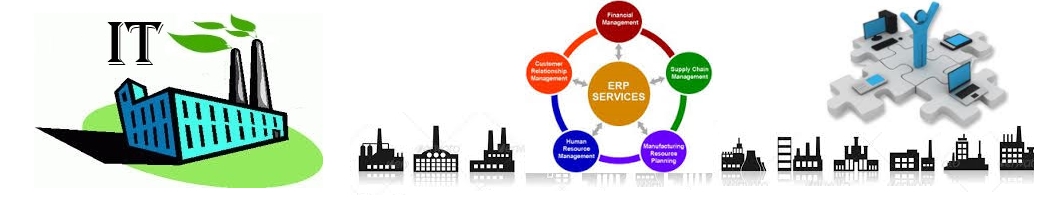

| Enterprise Resource Planning | Enterprise Resource Planning (ERP) is an integrated computer applications to plan and support execution of business functions in the manufacturing enterprise. ERP relates to product development in the following ways. ERP applications will contain product structure data (bills of material) generated during development. Some ERP applications also provide some product data management functionality. Finally, ERP is the tool to help forecast new product demand and order and stock materials to support product launch. |

| Environmental Stress Screening | Environmental Stress Screening (ESS) is a process which applies specific kinds of environmental stresses to products on an accelerated basis, but within their design parameters and limits to cause latent and intermittent flaws to become detectable failures. Also see Highly Accelerated Stress Screening (HASS). |

| EPD | Electronic Product Definition |

| EPL | Engineering Parts List |

| EPLD | Erasable Programmable Logic Device |

| EQFD | see Enhanced Quality Function Deployment |

| Ergonomics | Ergonomics is the science of designing products and work to be consistent with the capabilities and limitations of the human body. |

| ERP | see Enterprise Resource Planning |

| ESDA | see Electronic Systems Design Automation |

| ESL | see Electronic Systems Level |

| ESS | see Environmental Stress Screening |

| EST | Environmental Stress Testing |

| ETC | Estimate to Complete |

| Ethnographic Studies | A qualitative method of researching customer needs based on studying the anthropology or culture of the user. This method involves spending time in the field observing customers and their environment to better understand their lifestyle or culture as a basis for understanding their needs for a new product. A deep understanding of your customer can lead to fundamental insights that impact product design, feature sets, product positioning, marketing communications, advertising execution, etc. |

| EWI | Electronic Work Instruction |

| Expectancy Theory | The view that our effort will be greatest when we expect that we can perform the task at hand and that we expect to obtain rewards for our performance. |

| Experience Curve | Experience Curve (also known as a learning curve) is a mathematical model that relates the cost per unit (or labor time per unit) to the cumulative number of units produced in an exponentially decreasing manner. |

| EXPRESS | The information modeling language used to define the STEP standard (ISO 10303). |

| Extranet | An internet-based network that provides controlled access to outside parties. Also see Intranet. |

| Extreme Programming | Extreme Programming (XP) is one of the more popular lightweight, or agile development methods. In general, XP structures the “four basic activities of software development … coding, testing, listening, and designing.” XP structures coding based on the concepts of pair-programming and test-development. XP structures the testing activity by requiring automated tests that the team runs every day, several times a day. XP structures the listening activity through pair-programming and by requiring that the customer be part of the team and be on-site. Lastly, XP structures the designing activity by encouraging developers to use test-first development: define a test, then code until the test passes, then proceed to the next test. There is no big-design-up-front stage in an XP project. |

| Failure | A deficiency, defect, nonperformance or nonconformance with specified requirements. An item of equipment has suffered a failure when it is no longer capable of fulfilling one or more of its intended functions. Note that an item does not need to be completely unable to function to have suffered a failure. |

| Failure Analysis | Failure Analysis is a collection of techniques to determine the root cause of a component or process defect or failure. |

| Failure in Time | Failure in Time – a reliability measure usually expressed in failures per 10 to the 9th power hours. |

| Failure Mode | A particular way in which failures occur, independent of the reason for failure. |

| Failure Modes and Effects Analysis | Failure Modes and Effects Analysis (FMEA) is a procedure in which each potential failure mode in every sub-item of an item is analyzed to determine its effect on other sub-items and on the required function of the item. It is used to identify potential failure modes and their associated causes/mechanisms, consider risks of these failure modes, and identify mitigating actions to reduce the probability or impact of the failure. |

| Failure Modes, Effects and Criticality Analysis | Failure Modes, Effects and Criticality Analysis is a procedure that is performed after a failure mode and effects analysis to classify each potential failure effect according to its severity and probability of occurrence. |

| Failure Reporting and Corrective Action System | Failure Reporting and Corrective Action System (FRACAS) is a closed-loop system to capture reports of failure from customers or service technicians in the field or from the factory, analyze these reports, detect trends or problems, and use this analysis to take corrective action in the design, component selection, supplier selection, manufacturing process, or operating manual of the product. Features of a FRACAS system include a database manager, tracking system for document controls, user definable reports which allow selection of data elements and sort options, and search functions. |

| FAST | see Function Analysis System Technique |

| FAT | Factory Acceptance Testing |

| Fault Tree Analysis | Fault Tree Analysis is a top-down, hierarchical analysis of faults to identify the various fault mechanisms and their cause. It graphically describes the cause and effect relationships that result in major failures. The fault or major failure being analyzed is identified as the “top event.” All of the possible causes of the top event are identified in a tree using “or” nodes for independent causes and “and” nodes for multiple causes that must exist concurrently for a failure to occur. |

| FCA | see Functional Configuration Audit |

| FCT | Fast Cycle Time |

| FDA | Food and Drug Administration |

| FDL | Fault Detection and Localization (proposed IEEE standard) |

| FEA | see Finite Element Analysis |

| Feasibility | Capable of being completed to meet goals. The feasibility of a proposed new product has two dimensions: a) Technical Feasibility (i.e., will the product work?) and b) Financial Feasibility (i.e., will the product make an adequate return on investment for the enterprise?) |

| Feature | 1. Features are elements of the product that provide a distinctive benefit to the customer and are often highlighted in describing the benefits of the product to the customer. Features are the differentiating functionality of a product. This functionality may not be available in other products, or it may not be available with the same quality characteristics. 2. Features are geometric entities that have meaning in the definition and manufacture of a product. Examples of features are through-holes, bosses, bends, chamfers, slots, etc. |

| Features Technology | Features Technology – a variation of group technology with a focus on coding and classifying based on part features. |

| FEM | see Finite Element Model |

| Field Replaceable Unit | A collection of hardware or software that is installed or removed from a product as a single serviceable entity. The composition of product FRU’s is determined by the integrated product team. |