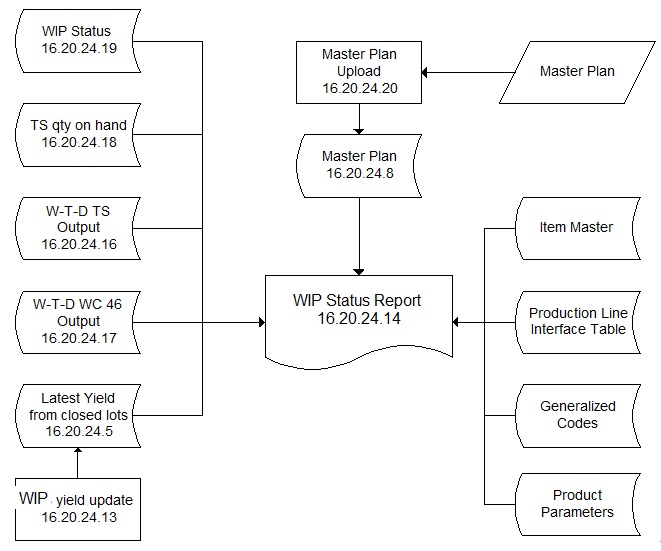

1. Overview

The following specification is aimed for a WIP status report for HK factory but including those going to PRC factory for gluing and directly shipped from PRC.

2. Generation of Data

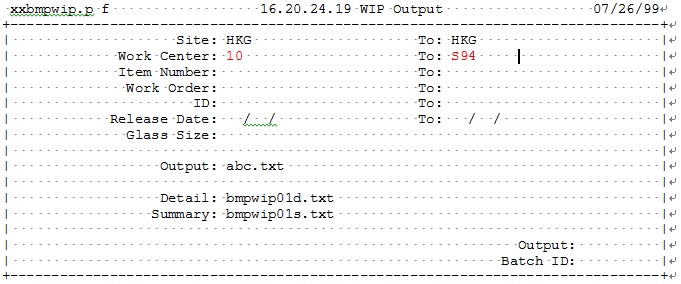

2.1 WIP Status per Work Center (16.20.24.19) – daily

- It gives the on hand qty of each work center at 0:00 that day.

- Database fields are arranged in sequence of work center codes found in work center table.

- Maximum array size is 130 work centers.

- Any change to work center, add or delete, must be done after the report generation of that day.

- This job must be done right after the system restart from backup. No shopfloor feedback is allowed during the process.

- Output Format:

“TP2” “3322 160 59231” 0 0 910 0 0 26606 7575 4559 0 32566 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

“tp2” “3322 161 00241” 0 0 0 0 0 0 0 0 0 2300 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

“tp2” “3322 161 00521” 0 0 0 0 0 0 0 0 0 6760 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

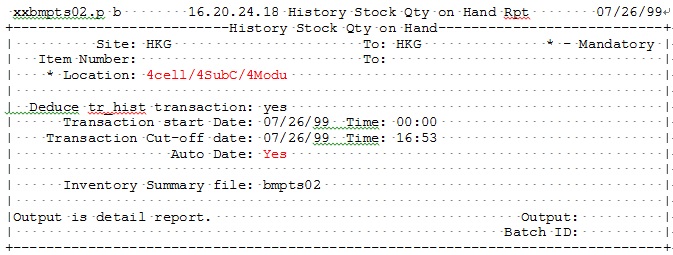

2.2 Technical Stock on hand (16.20.24.18) – daily

- It gives the stock on hand of each technical stock location at 0:00 that day.

- Data fields : pn, ts_location, current_onhand, xaction_qty_in_selected_date_range, calculated_onhand_at_start_time.

- When Auto Date=Yes, selected date range will be today’s 0:00 to current time.

- Output Format:

“ld_part” “ld_loc” “ld_qty_oh” 07/26/99 “02:17”

“3322 138 86621” “4cell” 68 0 68

“3322 160 52321” “4cell” 1 0 1

“3322 160 54591” “4subc” 339 0 339

“3322 160 55732” “4modu” 84 0 84

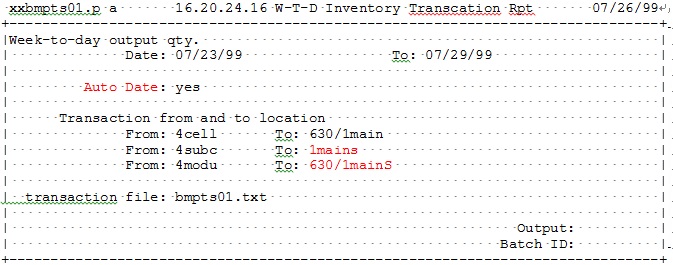

2.3 Week-To-Day Technical Stock Output (16.20.24.16) – daily

- It gives the week-to-day total output from technical stock locations.

- When auto-date is set to yes, the selected date range will be from last Friday to current week Thursday.

- Selected transaction and calculation method are as followings (4Cell as example) :

| Loc | Tr_type | Address | qty_change | Qty to sum |

| 4Cell | ISS-TR | 1main | -500 | 500 |

| 4Cell | ISS-TR | 630 | -1000 | 1000 |

| 1Main | ISS-TR | 4Cell | -200 | -200 |

| 630 | ISS-TR | 4Cell | -100 | -100 |

| Total O/P: | 1200 |

- Output Format:

“pt_part” “tr_loc” “tr_qty_chg” 07/26/99

“3322 160 51481” “4SUBC” 1130

“3322 160 55191” “4SUBC” 2322

“3322 160 55281” “4SUBC” 711

“3322 160 55321” “4CELL” 7609

“3322 160 55331” “4CELL” 12911

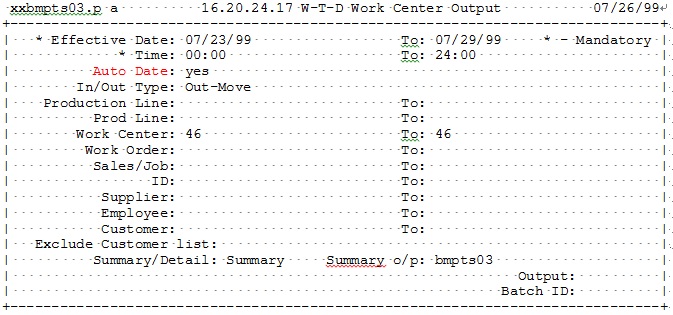

2.4 Week-To-Day Work Center Output (16.20.24.17) – daily

- It gives the week-to-day output qty of work center 46 which is defined as the output of HK factory to PRC cutoff at 0:00 of that day.

- When auto-date is set to yes, the selected date range will be from last Friday 0:00 to current week Thursday 24:00.

- Output Format:

“tp2” “3322 160 59231” “LPA7569-1A BONDED CELL” “46” 3263

“tp2” “9360 276 30112” “LPH7764-1” “46” 10058

“TP2” “9360 277 30112” “LPH7555-3” “46” 13543

“tp3” “3322 160 54561” “LPH7408-3 GLUED CELL” “46” 1274

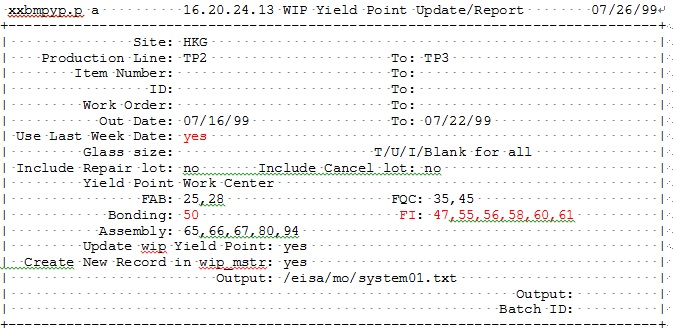

2.5 Yield Point Update (16.20.24.13) – weekly

- It gives a weekly update on the 5 pre-defined yield points based on lots closed in the past week.

- Currently only defined for HK yield capturing only. Additional yield points will be required for PRC operation.

- Default yield should be updated manually for new project.

- Output Format:

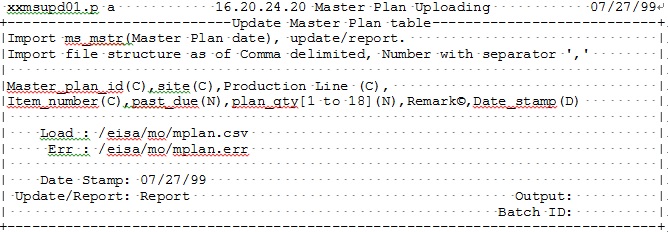

2.6 Master Plan Upload (16.20.24.13) Weekly

- This function is built for direct upload from Excel spreadsheet on weekly basis, expected to be done on Friday noon time.

- Excel format must follow the specification displayed on the screen. Further, file must be saved in csv format.

- The date stamp must be same as the one input on screen for validation purpose.

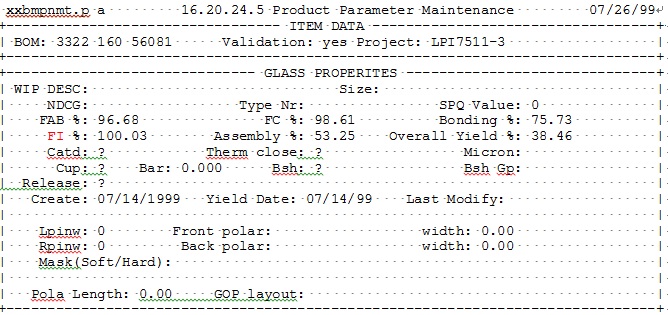

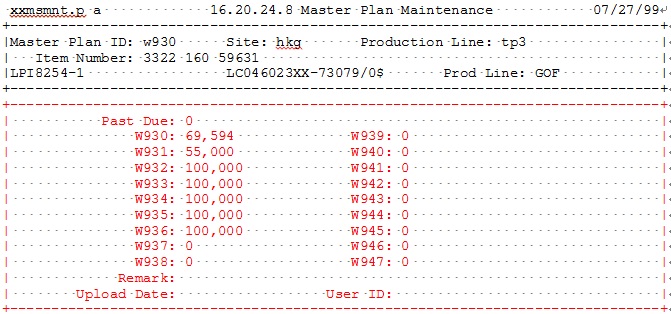

2.6 Master Plan Maintenance (16.20.24.5) – daily

- The maintenance of master plan is expected to be done off the Mfg/Pro and upload on weekly basis until full maintenance function is available.

- Full master plan maintenance function include new master plan generation from prior data with back log consideration, frozen windows, security…etc.

3. Report Printing and Definition

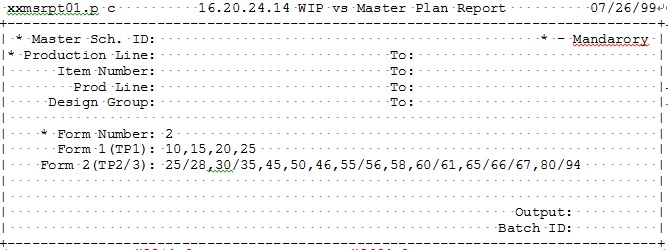

3.1 Selection Screen

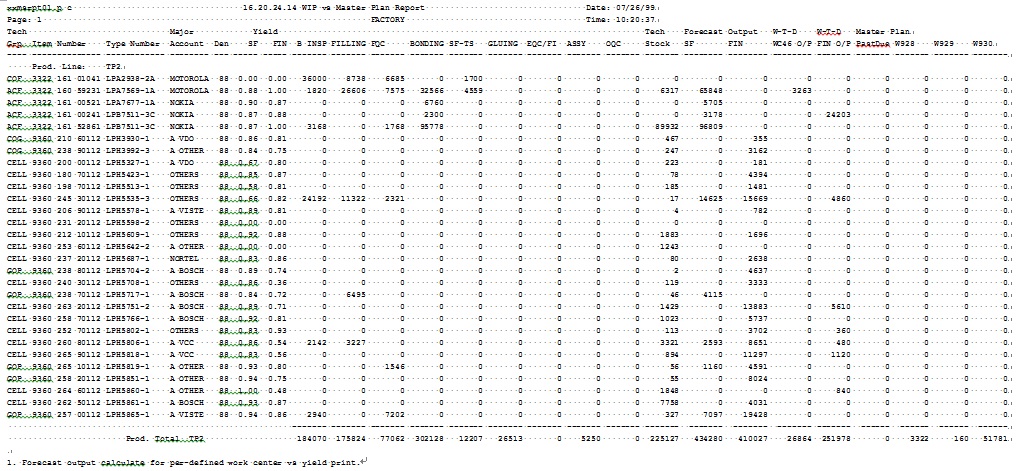

3.2 Field Definition for Form 2 (TP2/3)

- Technology(Tech Grp) = product line from Item Master

- Type Number = desc1 from item master

- Major Account = design group from item master

- Density (Den) = density from product parameter table

- Yield Semi-finishing (Yld SF) = fab * fqc * bonding yield from product parameter table

- Yeld Finishing (Yld Fin) = fab * fqc * bonding * fi * assy yield from product parameter table

- Queued Qty in Work Center

- S&B = wc 25 + 28 + 30

- Filling = wc 35

- FQC = wc 45

- Bonding = wc 50

- SF-TS = wc 46

- Gluing = wc 47+ 55 + 56

- FI = wc 58 + 60 + 61

- Assy = wc 62 + 65 + 66 + 67

- OQC = 80 + 94

- Technical Stock = Total on hand qty of all technical stock locations

- Forecast Output

- Semi-Finishing (SF) =

Wc (25 + 28 + 30) * fab * fqc * bonding yield

+ Wc (35 + 45) * fqc * bonding yield

+ Wc (50) * bonding yield

- Finishing (FIN) =

Semi-finishing O/P * fi * assy yield

+ Wc (46 + 47 + 55 + 56 + 58 + 60 + 61) * fi * assy yield

+ Wc (62 + 65 + 66 + 67) * assy yield

+ Wc (80+94) * 100% yield

- Week-To-Day (W-T-D) WC46 O/P = total output qty of work center 46 from last Friday to current week Thursday. It is considered as the output of HK Factory to PRC under production line TP3.

- Week-To-Day (W-T-D) FIN O/P = total output qty of technical stock locations from last Friday to current week Thursday

- Master Plan (HK) = Past Due, week n, week n+1 and week n+2 of master plan table ms_mstr.