1. Introduction

For trace rework situation for each lot , the mother lot, of which the sub-lot create the rework modules, must be indicated at rework order . So , all rework material must be by mother lot when they return warehouse , and one rework order must reflect one mother lot.

2. Responsibility

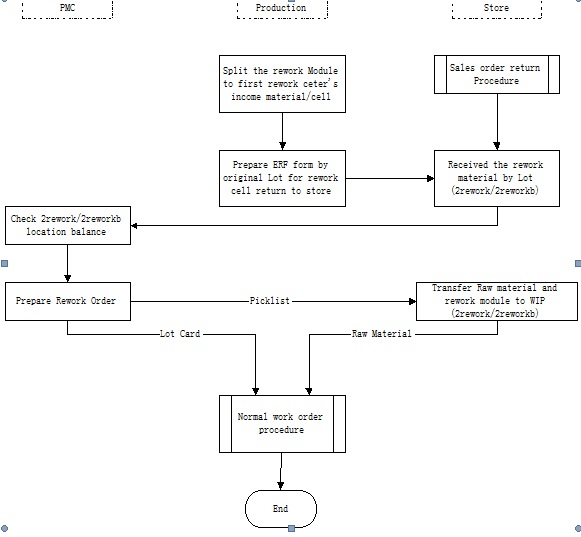

Production: Split the rework module to first rework center’s income material for internal rework module and fill ERF form return to Store

PMC : issue rework order according 2REWORK/2REWORK location situation.

Store :

(1) Split the rework module to first rework center’s income material for customer return rework module .

(2) fill MAR form and ERF form to issue module from 5qartn/5qartnb (see sales return procedure).

(3) issue rework materials to WIP according rework order.

3. Procedure

- When PMC create new work order , the mother lot ID must be input at ‘Sales/Job’ field . So after split to sub-lots, the mother lot ID will be printed on each lot card.

- Production Split the rework module to first rework center’s income materials for internal rework module. For example, if Assembly return FG#7366-1 to Store and they think it need be rework from 55 work center , they must split FG# to material list : Sub-Assb#1 (92999), Sub-Assb#2(55999).

- Production fill ERF form use the material list as above. And the mother lot ,of which the rework item create its sub-lot, must be filled at ERF. The mother lot ID can be found on each Lot card.

- For customer return rework module, Warehouse need split the rework module to first rework center’s income materials. The split method is same as Production. Two (MAR / ERF) forms must be filled (see sales return procedure) at same time and must indicate each other .And the mother , if there is ,should also be indicated.

- Warehouse receive rework material and keep it in store separate by mother lot . the mother lot ID must input at ‘reference ‘ field in ‘unplan receipt’ screen.

- Customer return rework module must be issued (unplan issue) from 5qartn/5qartnb (see sales return procedure).

- PMC check 2rework / 2reworkb locations balance and issue new rework order under the ‘reference No’ which indicated mother lot ID. One rework order reflect one mother lot ID.

- The original mother lot ID (not rework order mother lot) must be input at ‘Sales/Job’ field in ‘work order maintenance’, when PMC issue new rework order .

- Warehouse issue rework material under the mother lot ID on the pick list. The ‘reference’ need not be traced when the material transfer from 2rework/2reworkb to 2wip/2wipb.

- Rework order process on work center and goods receipt is same as normal work order

6. Flow Chart